AI Predictive Maintenance: Stop Waiting for Things to Break

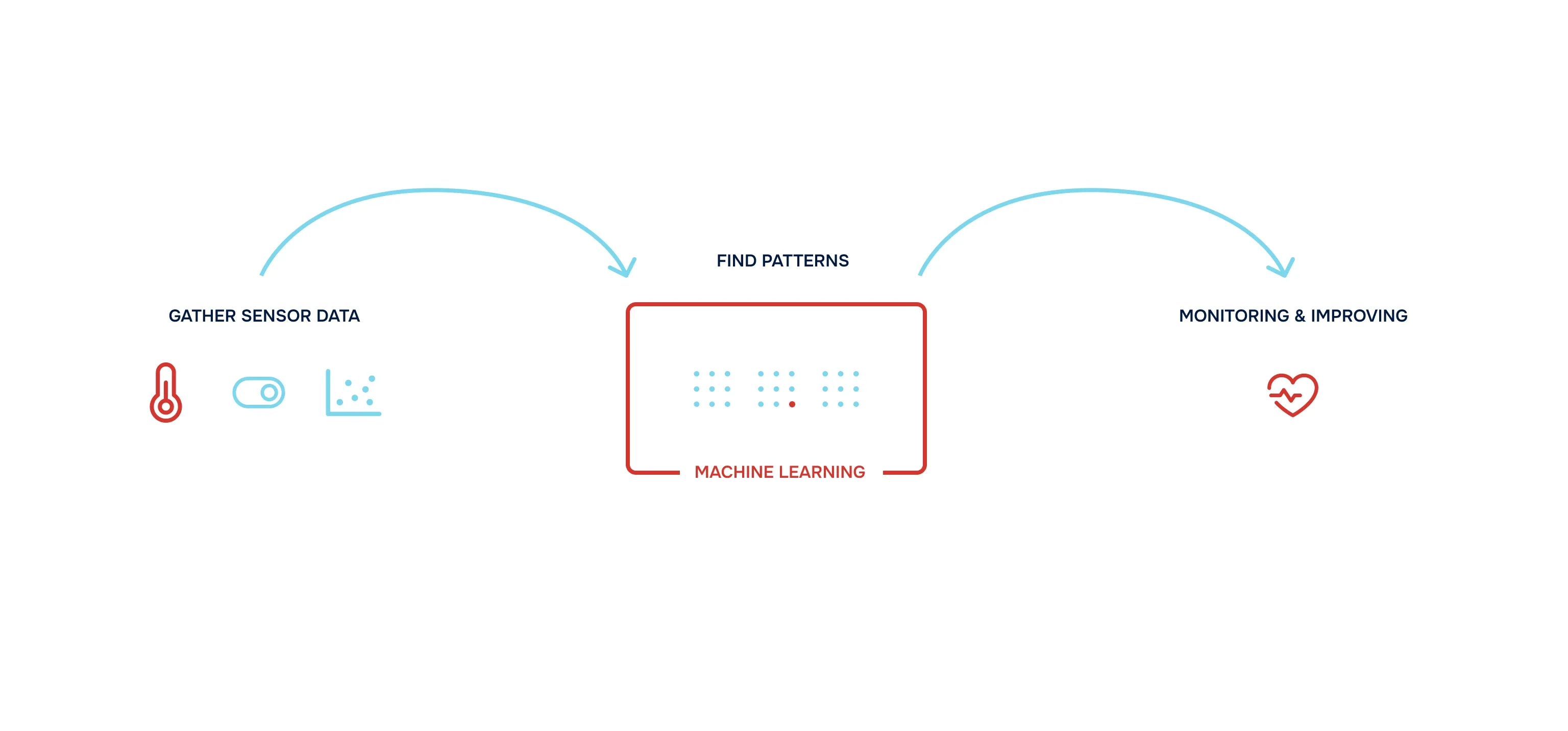

AI predictive maintenance uses past data and realtime sensors to predict failures ahead of time.

The factory floor is humming. Machines are running smoothly. Everything looks perfect. Then suddenly... your most critical production line dies. Again. And just like that, you're looking at thousands in lost revenue, emergency repair costs, and very unhappy customers.

Sound familiar?

Most companies are still playing maintenance roulette, either fixing things when they break (expensive) or maintaining everything on rigid schedules (wasteful). That's where AI predictive maintenance comes in.

Instead of crossing your fingers and hoping nothing breaks, smart sensors and machine learning algorithms analyze time series data to spot trouble weeks or even months before disaster strikes. We're talking 10-40% cost reduction, 50% less downtime, and equipment that lasts significantly longer.

The Good, The Bad, and The Reality Check

When does AI predictive maintenance work?

No more emergency calls about broken production lines. The AI tells you exactly when maintenance is needed, so you can schedule it during planned downtime.

Companies report saving 10-40% on maintenance costs while boosting productivity by up to 20%. That's real money, not marketing fluff.

Equipment failures don't just cost money, they can hurt people. Predictive maintenance catches dangerous conditions before someone gets injured.

But Let's Be Real About the Challenges

You'll need sensors, software, data infrastructure, and people who know what they're doing. The upfront investment can be substantial.

If your sensors are miscalibrated or your data is messy, your AI will give you useless predictions. Data quality is everything.

False Alarms Are Annoying: Poorly tuned systems will make your team stop trusting the alerts. Getting the sensitivity right takes time.

How to do predictive maintenance?

Step 1: Teaching Machines to Talk

Your equipment is already generating tons of data—vibration patterns, temperature readings, pressure levels, electrical signatures. The trick is collecting all this information cleanly and consistently.

When sensors fail (and they will), smart systems use interpolation techniques to fill in the gaps.

Step 2: Finding Patterns in the Chaos

This is where time series analysis gets interesting. Your HVAC system behaves differently in summer versus winter. Your manufacturing equipment shows different stress patterns during peak production. AI learns these seasonal variations and separates normal fluctuations from actual problems.

The key insight? Equipment doesn't always break randomly. It follows predictable degradation patterns that smart algorithms can recognize.

Step 3: Two Ways to Learn

Step 3: Two Ways to Learn

Supervised Learning: When you have historical failure data, algorithms learn from past breakdowns to spot similar patterns. It's like having an experienced mechanic who remembers every failure they've seen.

Unsupervised Learning: Most equipment runs fine most of the time, so failure examples are rare. Anomaly detection algorithms learn what "normal" looks like and flag anything unusual, even without seeing failures before.

Both approaches help predict RUL (Remaining Useful Life)—basically answering "how much time do I have before this thing breaks?".

The Math Behind the Magic: This isn't just AI wizardry. It's backed by solid statistical analysis, correlation studies, and probability calculations that provide mathematical foundations for predictions.

Step 4: Keep Learning and Adapting

The best systems continuously monitor their own accuracy and retrain when needed. Equipment changes, operating conditions evolve, and your AI needs to keep up.

Examples of AI Predictive Maintenance

Smart Buildings: No More Sweltering Offices

Its the middle of summer, your building's AC dies, and suddenly 200 employees are melting while you wait for emergency repairs.

With predictive maintenance, sensors monitor your HVAC system's motor vibration, energy consumption, and component temperatures. When the AI notices early signs of compressor bearing wear, it alerts you x weeks ahead of failure.

Instead of emergency repairs during peak summer heat, you schedule the work during mild weather when the building load is lighter. No uncomfortable employees, no emergency repair premiums, no angry phone calls.

Wind Turbines: Catching Problems Before They Get Expensive

Wind turbines are basically giant machines stuck in the middle of nowhere, dealing with extreme weather and variable loads. When something breaks, you need specialized crews, heavy equipment, and favorable weather just to reach them.

The AI watches bearing temperatures, vibration patterns, and power output variations, learning that certain temperature signatures predict failures months ahead. When trouble is spotted, maintenance gets scheduled during low-wind periods when energy production losses are minimal.

One wind farm reported 30% lower maintenance costs after implementation. That's real money saved by being smart about timing.

Manufacturing: Keep the Line Moving

In automotive plants, a single welding robot failure can shut down the entire production line at costs of hundreds of thousands per hour.

The system monitors welding current signatures, robot positioning accuracy, and hydraulic pressures. When subtle electrical pattern changes indicate welding tip wear, replacement gets scheduled during the next planned changeover instead of mid-shift.

BMW rolled this out globally and stopped having unexpected production line failures. Sometimes the simple solutions are the most powerful.

What challenges can you face with Predictive Maintenance?

Not Enough Broken Things (No failure data)

Most equipment works fine most of the time, which means you don't have many failure examples to learn from. It's like trying to teach someone to recognize a rare disease when they've only seen healthy patients.

Drowning in Data (Too much noise in the data)

Modern factories generate terabytes of sensor data daily. Without good data management and filtering systems, you'll spend more time managing data than preventing failures.

Sensors Lie Sometimes (Defect and miscalibration)

Industrial environments are harsh. Sensors get dirty, miscalibrated, or just fail. Your system needs to be smart enough to detect when a sensor is giving bad information.

The Curse of Too Many Variables (Too much to process)

When you're monitoring hundreds of parameters simultaneously, traditional analysis methods break down. More variables doesn't always mean better predictions—sometimes it just means more confusion.

Summary - What is Predictive Maintenance

AI predictive maintenance isn't magic—it's smart use of data to stop playing equipment roulette. Yes, there's upfront investment and technical complexity. But companies that get it right see real returns: lower costs, higher reliability, and equipment that actually lasts longer.

The key is starting small, focusing on your most critical equipment, and learning as you go. Your future self (and your CFO) will thank you when you're scheduling maintenance instead of scrambling for emergency repairs.

Want to explore AI predictive maintenance for your operation? The technology is ready—the question is whether you're tired of playing breakdown roulette.